Specialist Technical Material Suppliers

Heat Treatment

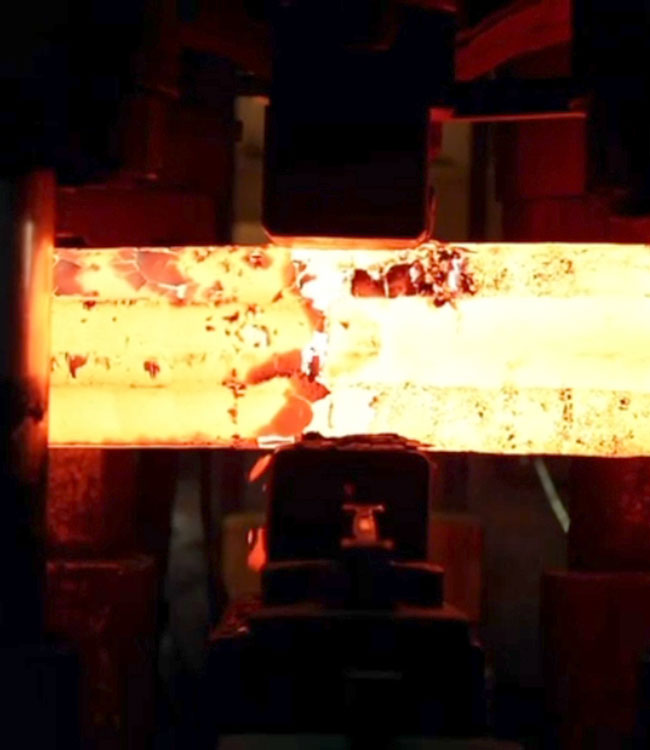

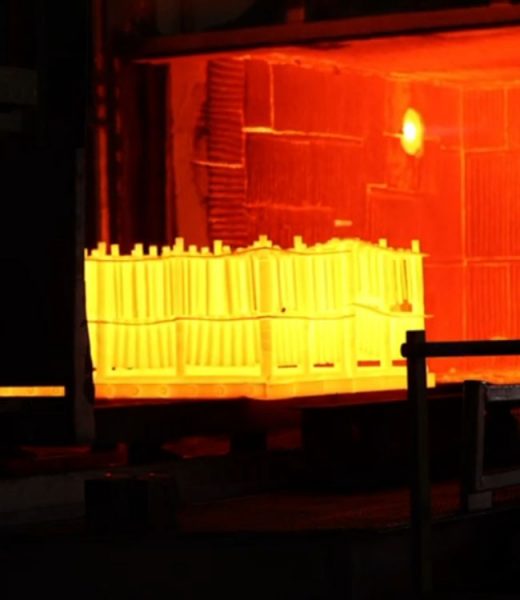

an Insight to The Heat treatment process at CRM

Heat treatment purpose

Heat treatment is a manufacturing process, heating metal to specific temperature then cooling it to harden the material. Can be used at different stages in the manufacturing process. Heat treatment makes the material stronger, durable, harder, ductile depending on what the material requires in order to perform properly.

- Hardening

- Annealing

- Tempering

- Case hardening

- Normalisation

Heat treatment is a process that involves heating and cooling metal materials in order to alter their physical and mechanical properties. It is used to harden, reduce brittleness, and improve machinability, as well as improve wear and fatigue resistance. It is used to restore damaged parts, transform their shape, or simply improve their overall appearance. Common techniques used in heat treatment include annealing, quenching, tempering, normalizing, and carburizing.

Technical specification treatments

It can take place in a furnace or by induction. The process typically involves the application of heat followed by a cooling process. During heat treatment, the material is heated to a particular temperature and held for a certain amount of time before cooling at a certain rate and temperature. It can cause permanent deformation of a material if it is not done properly and care must be taken when controlling the parameters and plays an essential role in the manufacturing and production process of metal components and products, resulting in improved performance and product life.

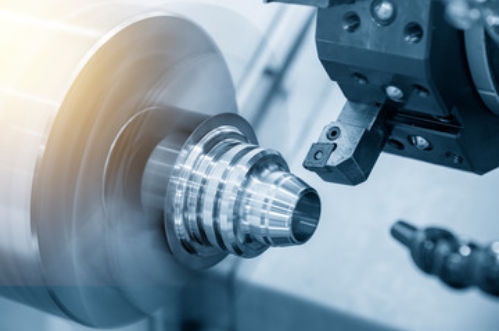

Heat treatment is typically used to enhance the hardness, strength, ductility and resistance to wear and corrosion in the metal. The three general heat treatment processes are Annealing, Tempering, and Quenching. Annealing is carried out to soften the metal, relieving any internal stresses created from machining which can cause the part to distort during machining.

Tempering is used to balance the strength and toughness of the metal. Quenching is used to harden the metal and make it more resistant to impact and wear. In addition to alloy characteristics, heat treatment has many other benefits such as stress relief, grain refinement, and improved dimensional stability.

INdustries WE Specialize in

Aviation

Automotive

defence

marine

oil and gas

petrochemical

Engineering

Find out more about our works within these Specialized areas

We would like to express our pleasure...

“

We would like to express our pleasure in regards to the product quality and services that we consistently receive from Corrosion Resistant Mayfair Ltd. We have always appreciated the quick response that we get and the general way that they undertake their business is excellent. We often find ourselves recommending the firm to others based upon the satisfaction that they provide us every time.

ENGINEERING – Purchasing supply Chain Manager – MA.

speak to an expert

get in touch

Speak to an expert, or request a call back at a time that suits you!