Specialist Technical Material Suppliers

Testing

the purpose of testing

his process happens to understand a materials behaviour

Commonly used for materials characteristics, fabrication, validation, failure investigation, engineering, engineering assessments.

Tensile, Charpy v, hardness testing, corrosion testing, intergranular testing, microstructure.

- Ultrasonic inspection

- Dypenetrant

- Magnetic particle inspection

- Positive material identification

- Third party inspection

Analysis technique, evaluates properties of material, components, structure / system for characteristics differences

Methods – leak testing, ultrasonic testing, electromagnetic testing, microwave testing

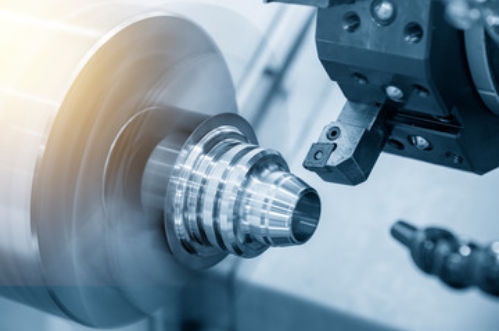

destructive testing

Destructive testing is a type of analysis used to evaluate the physical and mechanical properties of a material. It typically involves the removal of a sample of the material, which is then subjected to various tests like tensile, impact, hardness, and corrosion. These tests can give engineers and designers valuable insight into the material’s behaviour, which can help inform decision-making. Destructive testing can also help identify material deficiencies, allowing engineers to make changes and improvements before the product is finished. By carrying them out, engineers can ensure that the product meets all of the necessary specifications and that it will perform as expected in its intended environment.

elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est

elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo

non destructive testing

Non-destructive testing (NDT) is a process that is used to inspect and evaluate the properties of materials and components without causing any damage or degradation to the material. It involves the use of various techniques such as eddy current, ultrasound, acoustic emission, magnetic crack detection, radiography, holographic imaging, and visual testing. NDT is highly useful in a variety of industries since it enables the inspection of materials and components for flaws quickly and accurately. It also provides engineers and technicians with critical data about the condition of the material, allowing for appropriate corrective action to be taken if necessary. It can also detect tiny cracks and other defects that may not be visible to the naked eye. Additionally, It can help improve product quality, reduce costs, and improve safety, reliability, and performance.

INdustries WE Specialize in

Aviation

Automotive

defence

marine

oil and gas

petrochemical

Engineering

Find out more about our works within these Specialized areas

We would like to express our pleasure...

“

We would like to express our pleasure in regards to the product quality and services that we consistently receive from Corrosion Resistant Mayfair Ltd. We have always appreciated the quick response that we get and the general way that they undertake their business is excellent. We often find ourselves recommending the firm to others based upon the satisfaction that they provide us every time.

ENGINEERING – Purchasing supply Chain Manager – MA.

speak to an expert

get in touch

Speak to an expert, or request a call back at a time that suits you!